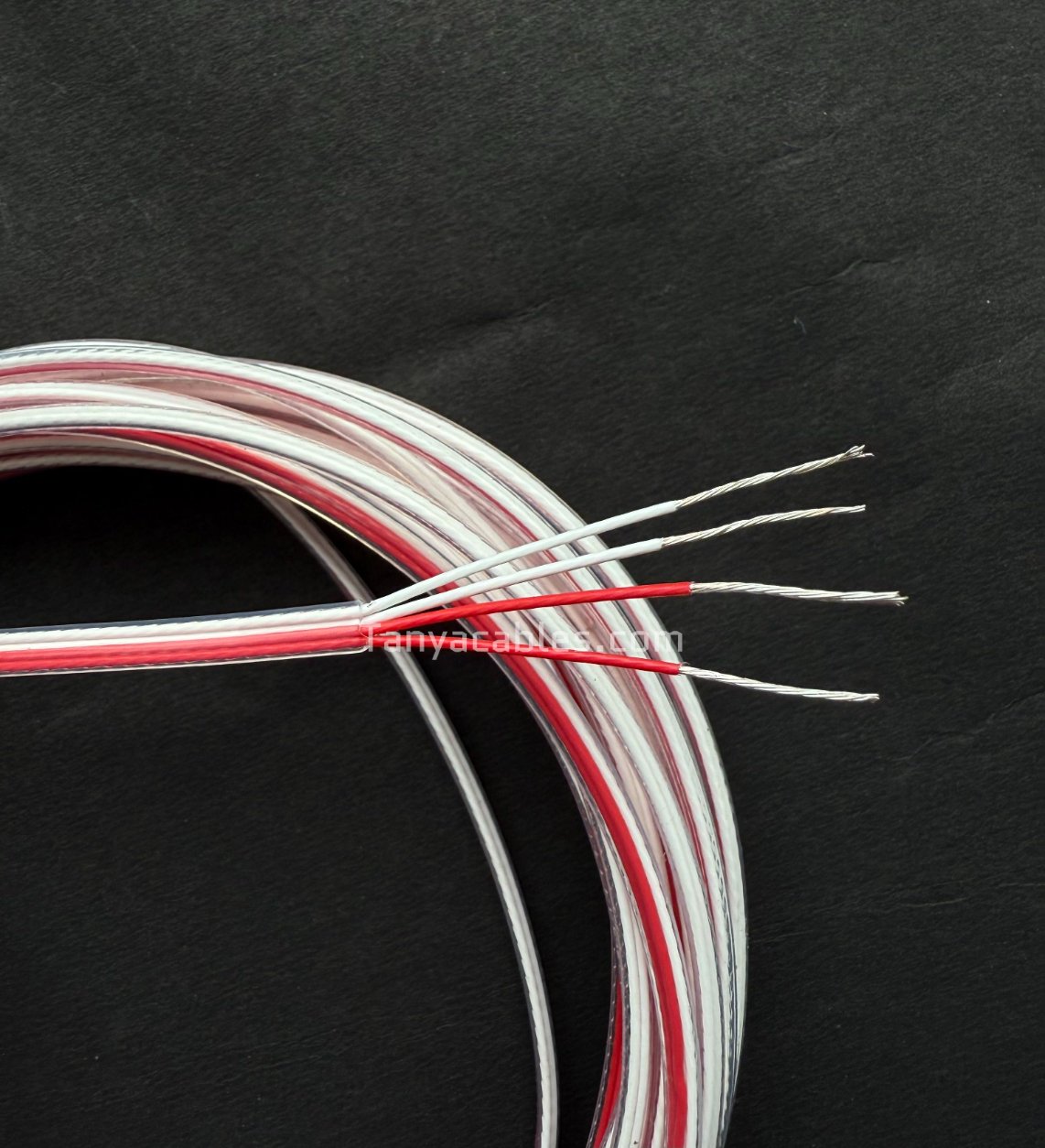

Engineered specifically for precision temperature measurement applications, Tanya Enterprises’

FEP RTD cables help maintain signal integrity over long cable runs and extended service life.

The stable electrical characteristics of FEP insulation minimize measurement drift and signal

degradation, making these cables suitable for critical processes where accuracy and

consistency are essential. Their flexibility and durability also allow for easy installation in control

panels, instrumentation trays, and confined industrial spaces, supporting long-term reliability in

automation, power generation, and process control systems.

Why use FEP RTD cables:

- Provides excellent thermal stability for accurate RTD signal transmission

- Offers low dielectric loss, minimizing signal distortion and measurement drift

- Resists chemicals, oils, and moisture, ensuring reliable performance in harsh

environments

- Maintains consistent electrical properties under continuous thermal cycling

- Flexible construction allows easy routing in panels, trays, and instrumentation systems

- Delivers a balance of performance, flexibility, and cost efficiency

Where FEP RTD cables are used:

- Industrial process control and automation systems

- Power generation and energy facilities

- Chemical and pharmaceutical plants

- Laboratories and testing equipment

- Instrumentation panels and control cabinets

Certificates

Technical specifications

HAR

HAR certificate No. CA01.00764

Rated voltage

450/750 VAC

Oil resistance

EN 50363-2-1

Short-circuit temperature

200°C

Rated temperature

-50 ÷ 90°C (@ fixed installation), -30 ÷ 90°C ( in dynamic installations )

Minimum bending radius

8D free movement, 6D @ fixed installation

Technical sheet

download

Available types of packaging